CORONA

TREATMENT

FOR EXTRUSION

Bilateral

TCB10

TCB15

TCB20-DS

Unilateral

TCU15

TCU20-DS

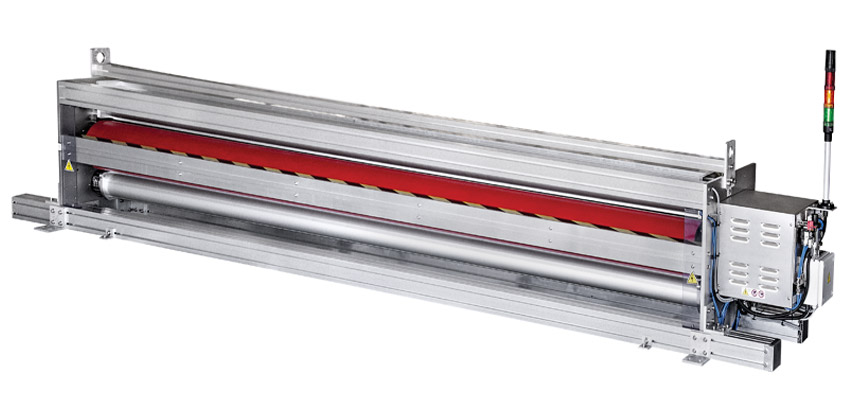

TC SERIES: Corona Treatments for Blown Film Extrusion

Corona treatment systems for increasing the wettability of insulating and flexible films on blown film extrusion equipment, in order to prepare them for subsequent printing and laminating processes.

Each system consists of a TC discharge unit, a GET electronic power generator, and an ozone extraction system.

The discharge station is designed to simplify all the most common use and maintenance operations: material insertion, electrode selection, air-gap electrode calibration, and silicone sheath sleeve replacement.

Electrode Bars:

• Possibility of partialisation in 10 mm steps for easy selection of the treatment band

• Segregated in protective boxes with pneumatic opening-closing mechanisms for easy material insertion.

Treatment rollers:

• Statically and dynamically balanced

• Covered with high-quality silicone sleeve (Optional: Vulcanisation)

Ozone suction system:

• Designed to keep the discharge electrodes well cooled and very clean.

Safety, sensors, and signals:

• The emergency stops, mobile guards, and electrode boxes are monitored by dual channel safety switches.

• Dedicated sensors for controlling the rotation of the treatment rollers and the extraction flow.

• Signals: Acoustic buzzer, 3-colour light column.

Main construction materials:

• Stainless steel and aluminium.

TCB10

| TECHNICAL SPECIFICATIONS | |

| Focus | Economic and practical |

| Application | Bubble outer sides (tubular) |

| Materials | Flexible insulating materials |

| Sides | 2 |

| Range | Up to 1500 mm |

| Electrode Bars | 1 per side, aluminium, sectionable by 10 mm (other options available) |

| Treatment rollers | 2, ø 100 mm, silicone sleeve coating |

| Guide rollers | Intake + outlet, natural aluminium |

TCB15-PLUS

| TECHNICAL SPECIFICATIONS | |

| Focus | High-performance and versatile |

| Application | Bubble outer sides (tubular) |

| Materials | Flexible insulating materials |

| Sides | 2 |

| Range | up to 3000 mm |

| Electrode Bars | 1 per side, aluminium, sectionable by 10 mm (other options available) |

| Treatment rollers | 2, ø 150 mm, silicone sleeve coating |

| Guide rollers | Intake (spiralled) + outlet, anodised aluminium |

TCB20-DS2

Double discharge

| TECHNICAL SPECIFICATIONS | |

| Focus | High-performance / extremely diverse processing operations |

| Application | Bubble outer sides (tubular) |

| Materials | Flexible insulating materials |

| Sides | 2 |

| Range | up to 3500 mm |

| Electrode Bars | 2 per side, aluminium, sectionable by 10 mm (other options available) |

| Treatment rollers | 2, ø 200 mm, silicone sleeve coating |

| Guide rollers | intake (spiralled) + outlet, anodised aluminium |

TCU15

| TECHNICAL SPECIFICATIONS | |

| Focus | High-performance and versatile |

| Application | bubble inner sides (foil) |

| Materials | Flexible insulating materials |

| Sides | 1 |

| Range | up to 2300 mm |

| Electrode Bars | 1, aluminium, sectionable by 10 mm (other options available) |

| Treatment rollers | 1, ø 150 mm, silicone sleeve coating |

| Guide rollers | Optional |

TCU20-DS2

Double discharge

| TECHNICAL SPECIFICATIONS | |

| Focus | High-performance / extremely diverse processing operations |

| Application | bubble inner sides (foil) |

| Materials | Flexible insulating materials |

| Sides | 1 |

| Range | up to 3500 mm |

| Electrode Bars | 2, aluminium, sectionable by 10 mm (other options available) |

| Treatment rollers | 1, ø 200 mm, silicone sleeve coating |

| Guide rollers | Optionals |